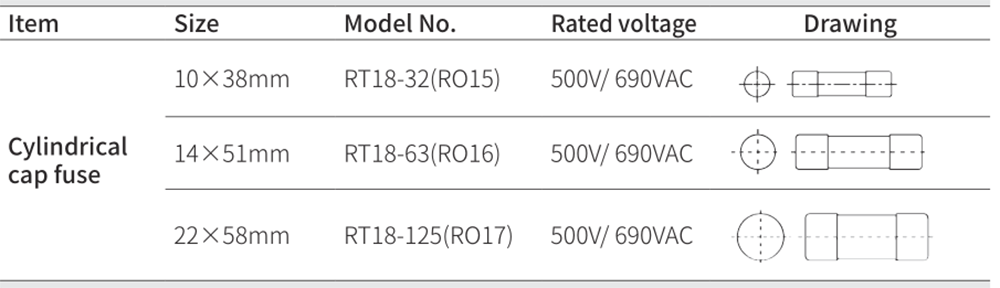

* Just as its name implies, the shape of cylindrical fuse is look like a cylinder. Cylinder fuse body is made of ceramic, porcelain, or glass. There is a thin copper wire or silver wire, or metal alloy strip in the middle of fuse. And also it has metal cap at each fuse end, which are used as contacts when it is inserted (in series) into the electric circuit. Usually, the metal cap is made of nickel plated red copper or silver-plated red copper which has high conductivity.

* Cylinder fuse body is filled up with granular or powder materials known as filler. There are various types of materials used as filler like sand, calcium carbonate, quartz etc.

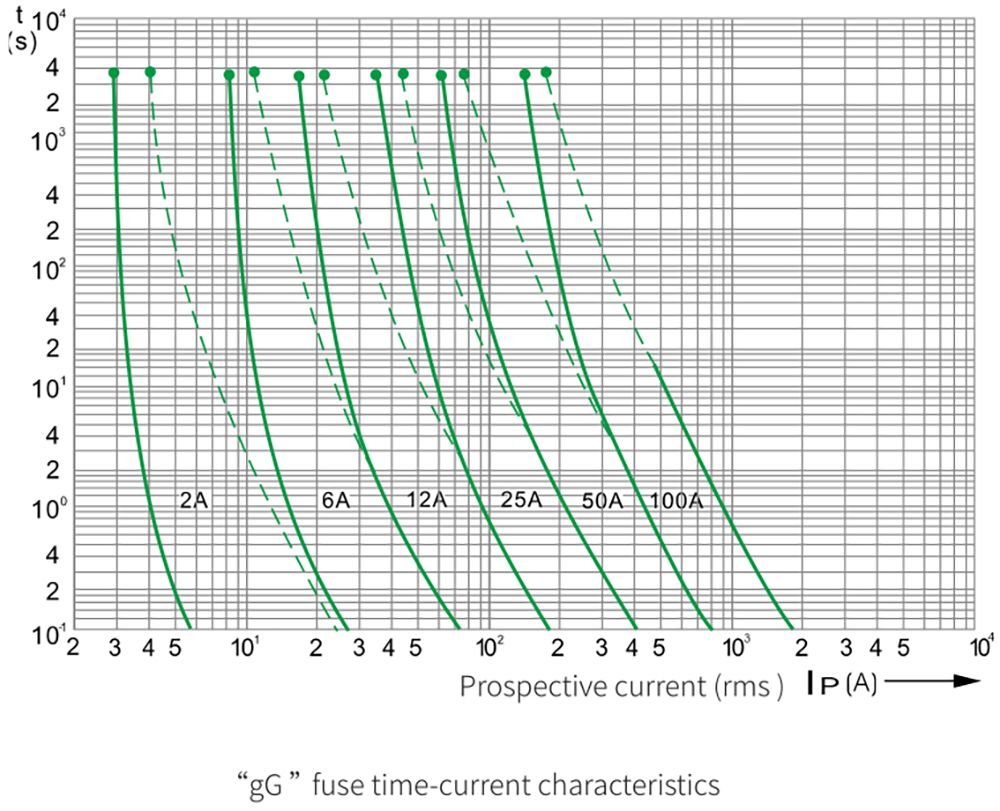

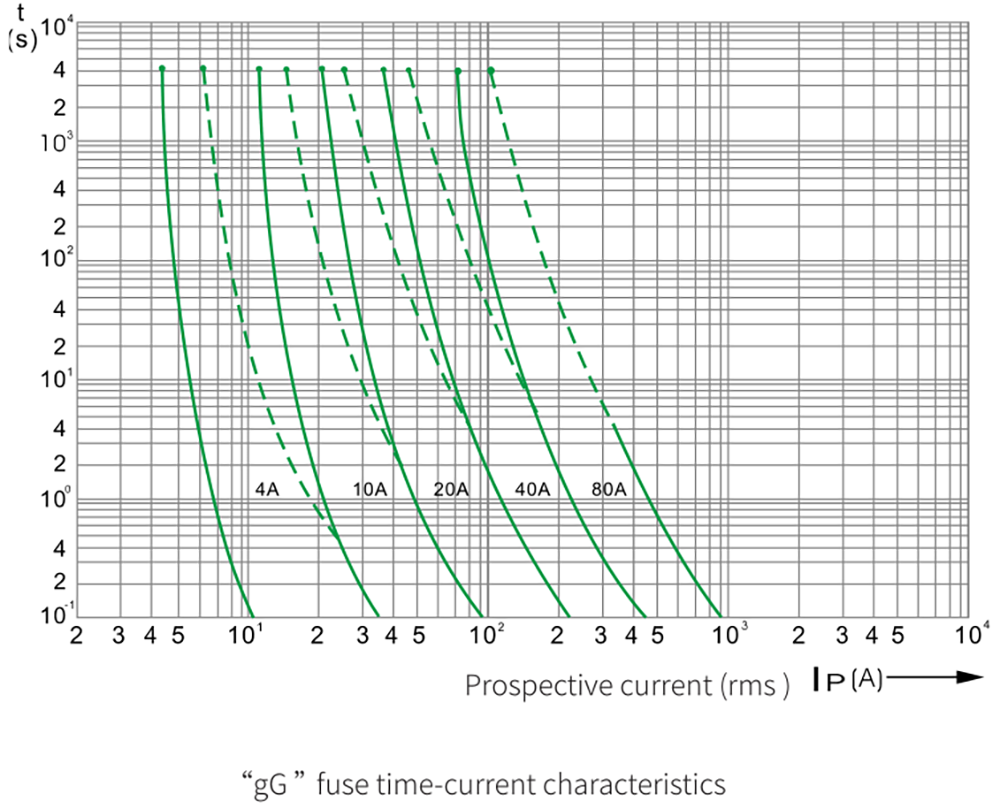

* The thin wire conductor is designed to fusing at a specific temperature when the circuit carries more than the rated current. When the wire fusing, the circuit breaks and no current flows. The powder in the fuse cartridge condenses and cools the vapor and quenches the arc there by interrupting the flow current.

* Cylinder fuses are widely applied in many different types of electrical and electronic equipment. They are not only protect the equipment from danger, but also prevent dangerous fires caused by overheating of the circuit. Once the cylindrical fuse has been overheats and the wire has been fusing, it does no longer works. Anew fuse must be installed to restore the current through the circuit. Cylinder fuses are replaced inside a holder. This is called a cartridge fuse carrier, fuse switch or fuse holder.