HGLR series isolating switch fuse group (hereinafter referred to as switch) is a multi pole, manual operated switch. The shell is made of glass fiber reinforced unsaturated polyester resin, which has high dielectric performance, protective ability and reliable safety.

The operating mechanism is an acceleration mechanism with spring energy storage and instantaneous release. The instantaneous connection and disconnection of multi breakpoint contact structure is independent of the speed of the operating handle, which greatly improves various electrical and mechanical properties.

The disconnector fuse group can ensure the safe and reliable connection and disconnection of the circuit. It has reliable protection against overcurrent or short circuits. The disconnected state is clearly visible.

Fuse Switch Disconnector Structure Characteristics

The Disconnector Fuse Group is the ideal solution for high-current connections and disconnections. Its modular design makes it easy to assemble according to your needs, while the integral structural design ensures stability. The spring energy storage mechanism allows for quick and easy connections and disconnections, even at high speeds.

- HGLR-63~400 disconnector fuse group adopts modular design structure, which can be assembled freely according to customer requirements.

- HGLR-630 adopts integral structural design to ensure the stability of product performance due to its high current.

The operating mechanism adopts a spring energy storage mechanism. When the product is connected and disconnected, the spring can be released instantly to realize rapid connection and disconnection (13.8 M / s), which is independent of the speed of the operating handle and greatly improves the ability to extinguish the arc.

The Disconnector Fuse Group is a safe and easy way to disconnect your electrical circuit. Made of high-quality glass fiber reinforced unsaturated polyester resin, this switch has a visual shield for easy disassembly and replacement of the fuse link. The Disconnector Fuse Group also has self-cleaning contacts for a reliable connection, and over-current and short-circuit safety protection functions.

Meet The Standard

International Standard

- IEC60947-1 low voltage switchgear and controlgear Part 1: General

- IEC60947-3 low voltage switchgear and control equipment, switches, isolators, disconnectors and fuse combinations

National Standard

- GB/T 14048.1 general rules for low voltage switchgear and controlgear

- GB/T 14048.3 low voltage switchgear and control equipment, switches, isolators, disconnectors and fuse combinations

- GB/T 4208-1993 degrees of protection for enclosed enclosures

- GB 13539.1 basic requirements for low voltage fuses

- GB 13539.2 supplementary requirements for fuses used by full-time personnel of low voltage fuses

Normal Working and Installation Conditions

Operating Environment

The maximum ambient air temperature shall not exceed +40℃, with a minimum of -5℃. The average temperature inside the building should not exceed +35℃ within a 24 hour period. The installation site should not be located more than 2000m above sea level.

When the maximum temperature is above 40℃, the relative humidity of the air should not exceed 50%. However, at lower temperatures, higher relative humidity is allowed; for example, 90% at 20℃. If condensation due to temperature changes should occur, special measures should be put in place.

The pollution level of the surrounding environment is level 3.isolator switch on or off

Installation

The switch shall be installed in a place without significant shaking, shock vibration and rain and snow invasion. At the same time, the installation place shall be free of explosive dangerous medium, and the medium shall be free of gas and dust sufficient to corrode metal and damage insulation.

Read on what is isolator switch?

Fuse Switch Disconnector fuse selection and fuse rated current comparison table.

Isolating switch fuse group different frame fuses

| Rated current of disconnector fuse group (A) | Rated current of fuse link (A) | Fuse size |

| 63 | 2、4、6、10、16、20、25、32、40、50、63 | 00C |

| 160 | 2、4、6、10、16、20、25、32、40、50、63、80、100、125、160 | 00 |

| 250 | 16、20、25、40、50、63、80、100、125、160、200、250 | 1 |

| 400 | 50、63、80、100、125、160、200、250、315、400 | 2 |

| 630 | 200、250、315、400、500、630 | 3 |

Electrical and mechanical properties of HGLR-63~630 disconnector fuse group

| Electrical parameters | Agreed heating current Ith (A) | 63 | 160 | 250 | 400 | 630 | ||

| Fuse size | 00C | 00 | 1 | 2 | 3 | |||

| Rated insulation voltage Ui | 800 | 800 | 800 | 800 | 800 | |||

| Dielectric strength (V) | 2000 | 2000 | 2000 | 2000 | 2000 | |||

| Rated impulse withstand voltage Uimp kV | 8 | 8 | 8 | 8 | 8 | |||

| Rated working current Ie (A) | 415V | AC-23B | 63 | 160 | 250 | 400 | 630 | |

| 690V | AC-21B | 40 | 100 | 200 | 315 | 400 | ||

| Limit short-circuit current(Iq)(KA) | 20 | 20 | 20 | 20 | 20 | |||

| Making and breaking capacity (arms) | Rated making capacity | 630 | 1600 | 2500 | 4000 | 6300 | ||

| Rated breaking capacity | 504 | 1280 | 2000 | 3200 | 5040 | |||

| Operational performance | Mechanical life | 1700 | 1400 | 1400 | 800 | 800 | ||

| Electrical life | 300 | 200 | 200 | 200 | 200 | |||

| Weight | 3 Poles | 1 | 1.8 | 3.2 | 4.8 | 16 | ||

| 4 Poles | 1.,3 | 2.3 | 4.5 | 6.1 | 19 | |||

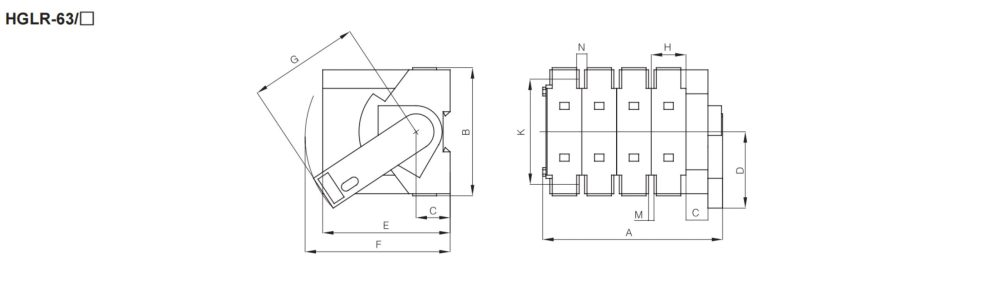

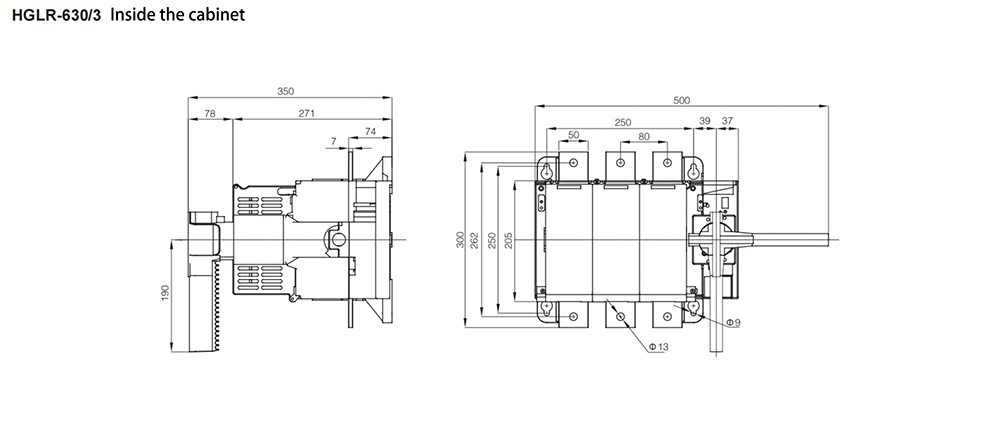

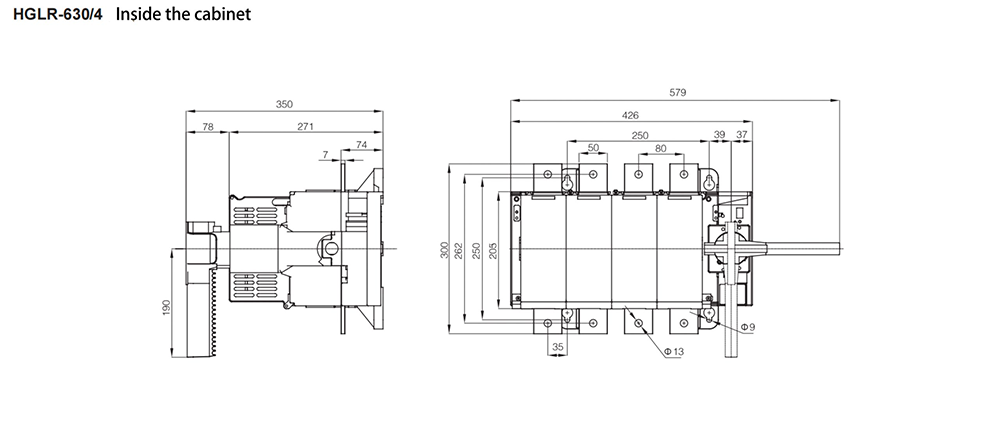

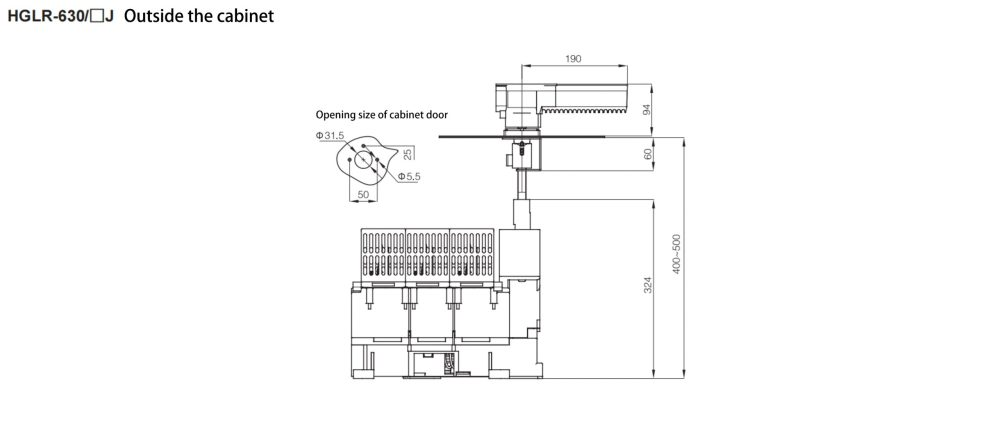

Fuse Switch Disconnector Outline and Installation Dimension (mm)

| Specifications | A | B | C | D | E | F | G | H | K | N | M |

| HGLR-63/3 | 134 | 118 | 31 | 70 | 118 | 134 | 102 | 32 | 97 | 9.5 | 5 |

| HGLR-63/4 | 166 | 118 | 31 | 70 | 118 | 134 | 102 | 32 | 97 | 9.5 | 5 |

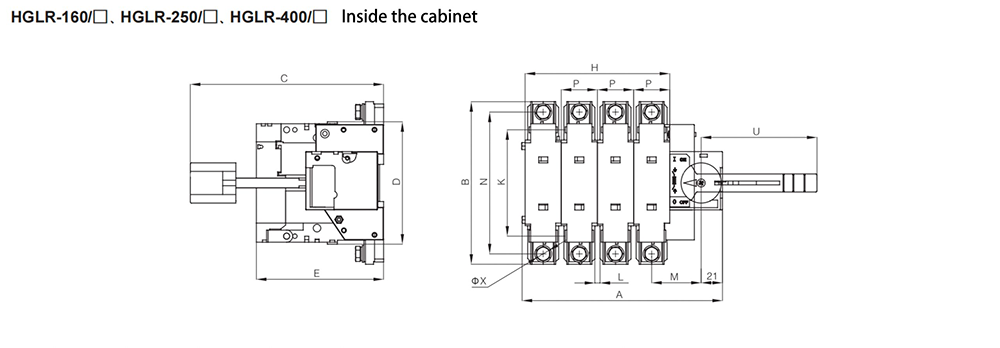

Fuse Switch Disconnector

| Specifications | A | B | C | D | E | H | M | K | N | P | U | L | ΦX |

| HGLR-160/3 | 165 | 162 | 192 | 118 | 127 | 108 | 67 | 90 | 141 | 36 | 115 | 5 | 8.8 |

| HGLR-160/4 | 200 | 162 | 192 | 118 | 127 | 144 | 67 | 90 | 141 | 36 | 115 | 5 | 8.8 |

| HGLR-250/3 | 236 | 195 | 200 | 160 | 146 | 180 | 93 | 137 | 165 | 60 | 145 | 6 | 11 |

| HGLR-250/4 | 296 | 195 | 200 | 160 | 146 | 240 | 93 | 137 | 165 | 60 | 145 | 6 | 11 |

| HGLR-400/3 | 281 | 205 | 200 | 170 | 149 | 198 | 124 | 137 | 175 | 66 | 145 | 6 | 11 |

| HGLR-400/4 | 347 | 205 | 200 | 170 | 149 | 264 | 124 | 137 | 175 | 66 | 145 | 6 | 11 |

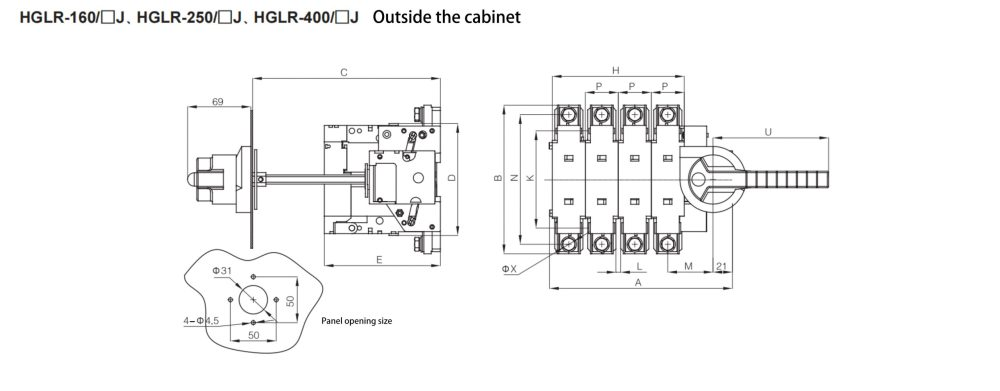

Fuse Switch Disconnector

| Specifications | A | B | C | D | E | H | M | K | N | P | U | L | ΦX |

| HGLR-160/3 | 165 | 162 | 150~300 | 118 | 127 | 108 | 67 | 90 | 141 | 36 | 126 | 5 | 8.8 |

| HGLR-160/4 | 200 | 162 | 150~300 | 118 | 127 | 144 | 67 | 90 | 141 | 36 | 126 | 5 | 8.8 |

| HGLR-250/3 | 236 | 195 | 150~300 | 160 | 146 | 180 | 93 | 137 | 165 | 60 | 126 | 6 | 11 |

| HGLR-250/4 | 296 | 195 | 150~300 | 160 | 146 | 240 | 93 | 137 | 165 | 60 | 126 | 6 | 11 |

| HGLR-400/3 | 281 | 205 | 150~300 | 170 | 149 | 198 | 124 | 137 | 175 | 66 | 126 | 6 | 11 |

| HGLR-400/4 | 347 | 205 | 150~300 | 170 | 149 | 264 | 124 | 137 | 175 | 66 | 126 | 6 | 11 |

Which application scenarios require industrial isolating switches?

The key role of industrial isolating switches

In an industrial environment, safety and efficiency are very important. This is especially true for high-power household appliances and machinery. To ensure smooth operation and protect personnel, industrial-grade isolating switches become indispensable components.

1.Heavy machinery and equipment

In industrial fields such as manufacturing, heavy machinery such as presses, lathes, and milling machines are common equipment in factories. These machines often run on high voltages and currents, which can be dangerous during maintenance or repairs. Industrial-grade isolating switches can safely isolate power before performing maintenance or other work. Work safely.

2.Industrial ovens and furnaces

Industrial ovens and furnaces for processes such as curing, annealing and heat treatment. They often handle extremely high temperatures and require precise control. isolating switches allow safe disconnection of power.

3.Motors and drives

Electric motors power various types of mechanical equipment in industrial settings. They are critical components of production lines and other processes. When performing maintenance, isolating switches ensure safe disconnection of the power supply, preventing any accidents.

4.High power welding equipment

Welding equipment in industrial environments often operates at high currents and voltages. Isolating switches to cut off power during maintenance or emergency situations. This adds an extra layer of safety for those working with welding machinery.

5.Three-phase motors and systems

Three-phase motors are common in large-scale industrial operations. They drive everything from conveyors to compressors. isolating switches designed for industrial use allow safe disconnection of power

6.High voltage transformer

Transformers are essential equipment in industrial facilities for regulating voltage levels. Because of the high voltages involved, isolating switches allow for safe disconnection of power during maintenance, inspection or repair.

In general, industrial-grade isolating switches are very important in environments where high-power household appliances and mechanical equipment operate. They provide a critical safety net by isolating power during maintenance or emergencies.load isolation switch

leave your question

GRL Electric Co., Ltd. is one of the leading companies in the Middle And High End market of low-voltage electric in China