Go all out to continue to promote | GRL Electric Hold October “5S” management summary meeting

At 16:30 pm on November 9th, GRL Electric held the October 5S on -site Management Summary Awards Conference.

The deputy deputy directors (deputy directors) and above management personnel, workshop leader, components, and finished database representatives were present. , Attended the meeting.

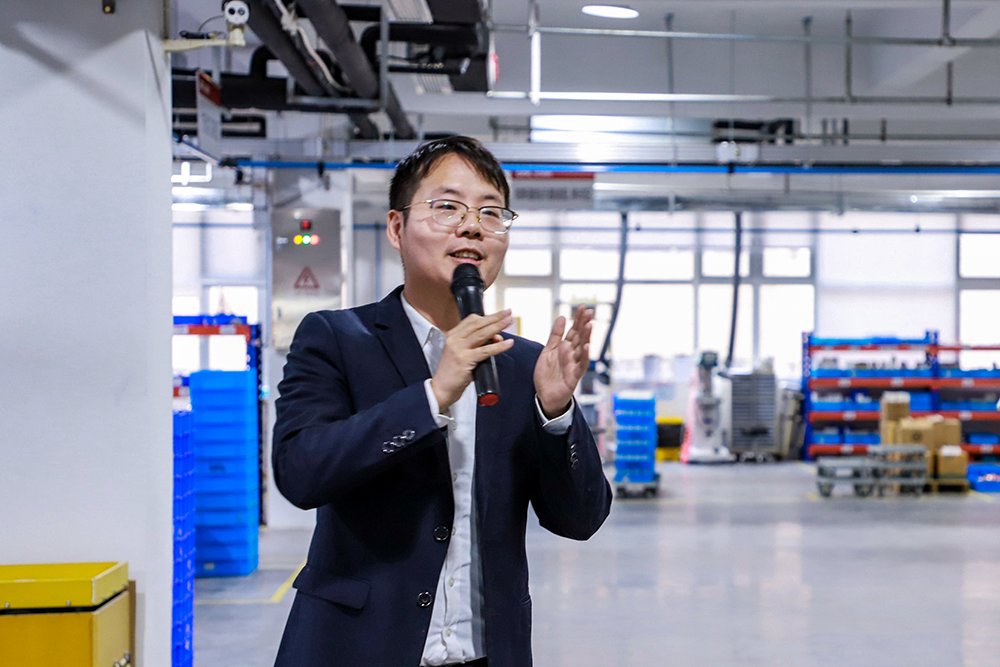

▲ The conference was chaired by the manager of the Ministry of Personnel Administration

▲ Ni Jufeng, Deputy President of Operation, summarize his speech

At the meeting, Ni Jufeng, the vice president of operation, summarized the 5S management in August: After passing the “5S” inspection in October, the overall situation of each region continued to be well, but the details need to be improved and improved.

This month The temporary office area was relocated to the new office district. Some departments were organized quickly in a short period of time, but some departments were slightly slower. This month will not make specific evaluations.

I hope that all departments have changed in November. It is the procurement management department.management summary meeting

In October, in the “5S” assault spot check, it was found that the “Gold Workshop” and “raw material library” were not in place. Many areas did not meet the 5S management standards.

This shows that “5S” is not organized to check, not short -term temporary behavior, but to develop long -term unremitting improvement and improvement, continuous improvement, so that the scene can really achieve the role and purpose of 5S.

The inspection team conducted a comprehensive inspection and rating of each area. The inspection results mainly existing the following problems:

1. The phenomenon of random placement of materials, equipment, and other items still exists, especially some temporary items are placed at will;

2. The physical and regional logo does not match;

3. Positioning, fixed capacity, and fixed -point work need to be improved;

4. The corner and leakage oil treatment plan of the Golden Industry workshop needs to be improved;

5. Insufficient hygiene attention at the bottom of the production line and the corner of the area;

After inspection and selection of the GRL Electric 5S Management Committee, in the September “5S” management selection activities, the “excellent (red flag)” and “good (yellow flag)” were finally evaluated management summary meeting

The red flag and bonus were awarded by the general manager David Liu, and Huangqi was awarded by the chief of the technical worker Fan Lin. management summary meeting

5S flowing red flag

Administrative office

Procurement management department

Plan

Four -database of parts

Congratulate

5S flowing yellow flag

Production department

Fuse workshop 、Assembled a workshop

Assembly second workshop 、Equipment of three workshops

Golden Workshop 、mold workshop

Plan

Parts of parts 、Two Library Library

Three Library of Parts 、Ipinwood

Finished database two 、Zinpin Library Sanku

Finished database four storage 、Raw material library

Administrative office

Customer support department 、Brand promotion department

human resource department 、Product management department

Technology research and development 、Fuse project department

Department of Finance 、Engineering department

Plan 、Production department

Information Department 、Quality Management Department

Engineering department 、International sales department

treat

Leader’s speech

The general manager David Liu first made a concluding speech: The biggest highlight this time was that the two departments of the red flag changed, and at the same time, the department of the black flag was gone.management summary meeting

Originally, I rushed over to issue a black flag. It’s right. Of course, this is obviously that our 5S management has made progress, which is a difficult progress.

In the future, we need to use 5S management and safety management as the two features of GRL electrical.management summary meeting

The two highlights are displayed, and some cultural output is to be done. In fact, the best means of marketing is the scene. The scene is the responsible area of each department.management summary meeting

The scene of each excellent company shows the entire process in front of customers, letting you appreciate. This is a sign that attracts customers. All customers are more willing to put their orders in the company where 5S is better.

Because this makes them reassured, and they are also at ease. I put forward a hope here: There is no reason for our office area, and we must do better.management summary meeting

I just said that President Chi Kang said that such a large area of production can also be done well. It is easier to do well in our office area. So I hope everyone must go to the end. management summary meeting

View grl group information