Fuses work based on the principle of thermal dissipation—when current flows, resistance within the fuse element generates heat. If the generated heat surpasses the fuse material’s threshold, it melts and breaks the circuit. Understanding this balance of heat generation and dissipation is vital for designing effective fuses.

How does the fuse work?

Understanding the Basics of Fuses

1. What is a fuse?

A fuse is an electrical appliance that protects circuits and electrical equipment from short circuits and overloads. The IEC127 standard defines a fuse as a “fuse link”.

If it works, the fuse is in series with the protected circuit. When the circuit is short-circuited or severely overloaded, the fuse body automatically fuses and plays a protective role.

The most common is the fuse. The fuse is an electrical appliance that protects the circuit by melting the melt. It cannot be reused, and after the protection, the melt needs to be replaced.

The function of the fuse is mainly to protect the low-voltage power distribution system from short circuits, and some can also provide overload protection.

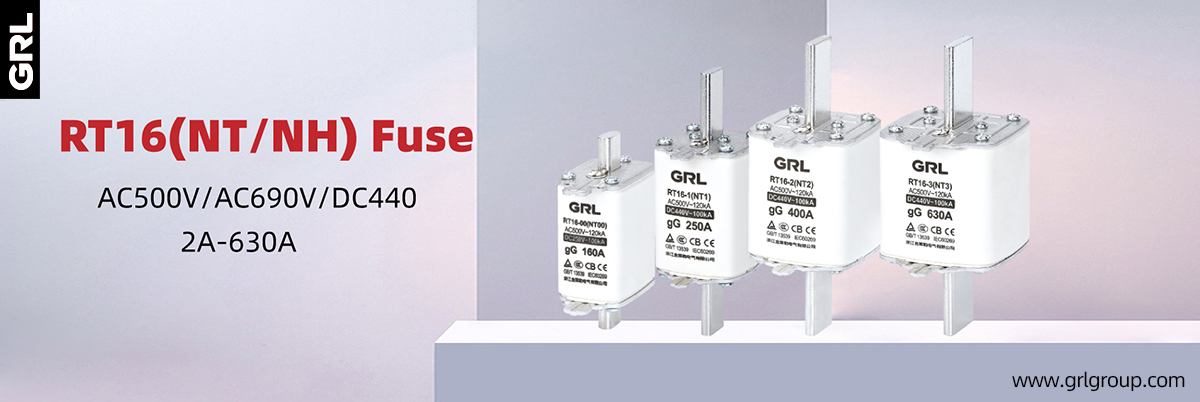

Click to view GRL fuse product>>

These two protection mechanisms serve different functions and respond to distinct fault conditions within an electrical system.

1. Short-Circuit Protection

Short-circuit protection prevents damage to equipment and wiring in the event of a short circuit—typically a sudden surge in current due to insulation failures or accidental contact within the circuit. When a short circuit occurs, the current rises sharply beyond safe limits, potentially causing severe damage or even fires.

Working Principle: In case of a short circuit, the current spike causes the fuse element (or link) inside the fuse to melt rapidly. This immediate reaction cuts off the current flow, thus protecting the downstream components.

Application: This protection is crucial in applications where sudden current spikes can cause catastrophic damage, such as in industrial equipment, household circuits, and other critical systems.

2. Overload Protection

Overload protection, on the other hand, handles situations of sustained high currents that don’t reach short-circuit levels. For instance, a motor under continuous heavy load can cause the current to exceed the normal operational range but without causing a short circuit.

Working Principle: The fuse element is sensitive to heat and responds to the accumulated effect of prolonged high current by gradually melting and finally breaking the circuit. This slower response allows temporary current fluctuations without unnecessary interruptions.

Application: Overload protection is essential for ensuring stable operation under long-term loads, helping prevent gradual overheating that could damage sensitive components over time.

2.How does the fuse work?

When current flows through a conductor, the conductor can heat up because of the presence of a certain resistance within the conductor.

And also the hot value follows this formula: Q=0.24I2RT within the formula, “Q” is that the calorific value; 0.24 is a constant; “I” is the current flowing through the conductor; “R” is the resistance of the conductor; “T” is the time for the current to flow through the conductor.

When the material and form of the fuse are determined, its resistance R is tremendously determined (If you do not add its temperature coefficient of resistance).

It heats up whilst current flows via it, and it heats up over time.

The size of the current and resistance determines the Thermal efficiency, and the shape of the fuse and its set up circumstance decide the efficiency of heat dissipation; if the efficiency of heat is much less than the efficiency of heat dissipation, the fuse will not be blown; if When the efficiency of heat is identical to the efficiency of heat dissipation, it’s going to now no longer fuse for a protracted time;

if the efficiency of heat is extra than the efficiency of heat dissipation, increasingly more heat might be generated, and due to the fact It has a sure particular heat and quality, and the boom in its heat is meditated with inside the boom in temperature.

When the temperature rises above the melting factor of the fuse, the fuse might be blown. This is the running precept of the low fuse.

From this principle, it should be known that the physical properties of the selected binder materials must be carefully studied when designing and manufacturing fuses and to ensure that they have consistent geometric dimensions.

Because these factors play an important role in whether the fuse can work normally. Also, when using it, be sure to install it correctly.

Click to view grl fuse link product>>

Read on Why the Fuse Holder Is an Essential Component of Every Household?>>

3.What are the types of commonly used fuses?

Type meaning of fuse

1.The plug-in fuse is simple in structure, low in price, and easy to replace. When in use, insert the porcelain cover into the porcelain seat and remove the porcelain cover to replace the fuse. Plug-in fuses are often used at the end of low-voltage lines or branch circuits with rated voltages of 380V and below and rated currents of 5~200A for short-circuit protection of lines and electrical equipment, and for overload protection in lighting circuits.

2.The fuse tube of the spiral fuse is equipped with quartz sand, a fuse wire and a fuse indicator with a small red dot. The quartz sand is used to enhance the arc extinguishing performance. After the fuse is blown, there is a clear indication.

Once the fuse is blown, the indicator will pop up immediately, which can be observed through the glass hole on the porcelain cap. It is regularly used in the electrical control equipment. It has a large breaking current and can be used for short-circuit protection in circuits with a voltage level of 500V and below and a current level of 200A or below.

3.There are 2 forms of enclosed fuses: filled fuses and unfilled fuses. Filled fuse typically use sq. ceramic ware tubes, that are crammed with quartz sand and melt, and have robust breaking capacity. The fuse tube is formed of steel paper, and also the two ends are detachable caps fabricated from brass. Melting sheet, it’s additional convenient to interchange the melt.

Enclosed fuse are utilized in circuits with voltage levels below 500V and current levels below 1kA; non-packed closed fuses pack the melt into a closed cylinder, with a rather smaller breaking capacity, and are used in power networks or distribution systems below 500V and 600A. In electrical equipment.

4.The fast fuse is principally used for short-circuit protection of semiconductor rectifier parts or rectifier devices. Because of the low overload capability of semiconductor components.

It will solely face up to an outsized overload current terribly very short amount of time, therefore the short-circuit protection is needed to possess the power to quickly fuse. Its structure is largely identical to that of the encircled fuse with filler, however the soften material and form are different.

It’s a variable-section melt with a formed deep groove punched from silver.

5.The self-resetting fuse uses metal because the melt and has high conduction at area temperature.

Once a short-circuit fault happens within the circuit, the short-circuit current generates an extreme temperature to chop-chop vaporize the metal, and also the gamified sodium exhibits a high resistance state, therefore limiting the short-circuit current; when the short-circuit current disappears, the temperature drops, and the metal sodium restores its original smart electrical conductivity.

The reset table fuse will solely limit the short-circuit current and can’t very break the circuit. The advantage is that there’s no ought to replace the melt, and it is reused’re not perfect.

Click to view grl group company information>>