GRL Information | GRL 2013 Lean Management Kick-off Conference was officially held

On March 2, the GRL 2023 Lean Management Kick-off Conference was officially held in the multi-function hall on the third floor of Building 2. All employees attended the event.

The meeting was presided over by Su Leqiang, manager of the Human Resources and Administration Department.

General Manager David Liu made a speech at the meeting. He believes that lean production is a management idea and methodology. The promotion of lean production cannot rely solely on a few workshop directors.

No matter how good their ability is, if the employees do not cooperate, everything is empty talk. Therefore, I think lean production depends on everyone.

All employees must truly understand the meaning of lean and do a good job in lean management. Starting from ourselves, starting from the team, and making all staff lean is our goal!

The practical significance of our lean production today is to solve the problems first, that is, improve efficiency, increase production capacity and speed up the delivery time. The center is better quality, faster delivery time and lower cost, which should be implemented closely around these three directions.

The vice president of the company’s operations explained to everyone the significance of “lean management”, the list of the “lean management” committee, and the “lean” system and plan of this year.

Mr. Ni explained the meaning of lean: “lean” means less investment, less consumption of resources and less time, especially to reduce the investment and consumption of non-renewable resources and achieve high quality;

“Benefit” means to produce more economic benefits, achieve the upgrading goal of the enterprise, and keep improving. To sum up, lean management is to eliminate waste under the goal of creating value.

Through lean management, eliminate all ineffective and non-value-added labor and waste, and take continuous improvement as the core.Kick-off Conference

Through lean management, safety assurance, quality-oriented, continuous cost reduction, punctual delivery, enhanced production flexibility, continuous improvement of production efficiency, zero defect and zero inventory, and enhanced team morale;

GRL Electric has established a Lean Implementation Committee and formulated the “Lean” system and plan for this year.Kick-off Conference

In the future, there will be project assessment, which aims to encourage and urge the project teams to make continuous progress in improvement.

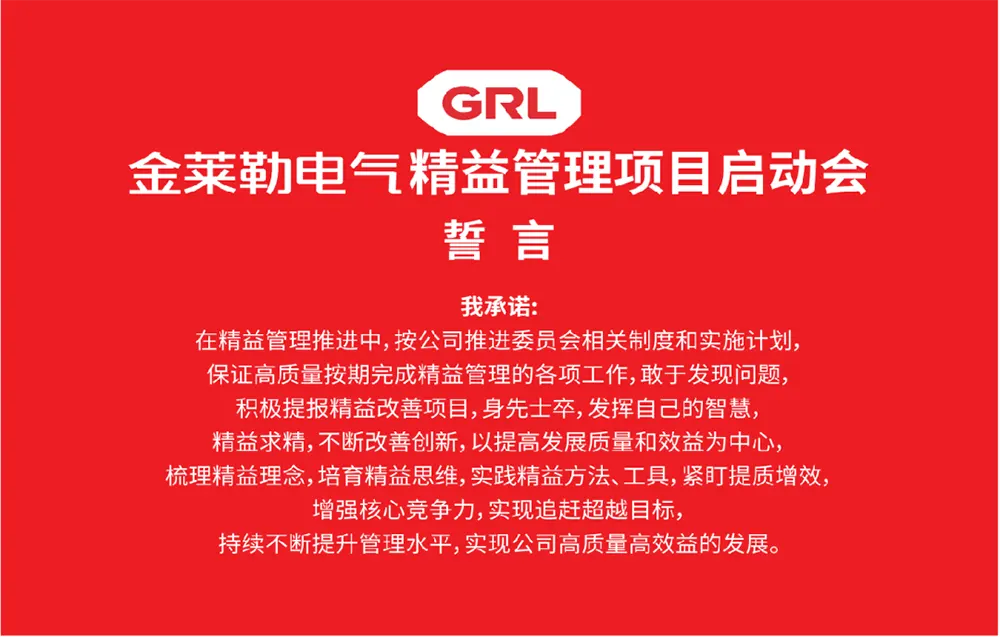

Then, under the leadership of Manager Su, all staff took the oath ceremony of lean management.

Under the leadership of General Manager Ni, the relevant responsible person signed his/her name on the banner of the lean management oath, and then took a group photo with all employees.Kick-off Conference

Lean management system is not a new task beyond the original work, but a more effective work method based on 5S management.Kick-off Conference

To implement lean management, we must first change our ideas. Only when thoughts and understanding are unified can actions be unified.Kick-off Conference

Therefore, leaders at all levels must change their concepts, transfer the management concept from traditional management to lean management, and then lead the staff to promote lean management.

Lean management is implemented in all departments of the company with the participation of all staff, involving operations, technology research and development, human resources, marketing, supply chain and support function systems, and forms an efficient lean strategic collaboration.

Eliminate waste, keep improving, make suggestions, implement, improve efficiency, reduce costs, build a lean management corporate culture, and achieve sustainable development.

View grl group information