Fuse-breaking protection for the Control box

GRL Electric fuses and fuse bases are used in electric control cabinets in BYD’s production workshop.

Overview

BYD is the largest electric car producer in the world. There are 220,000 employees and an annual output value of 35 billion USD.

BYD (Shenzhen) Electric Car Production Base is BYD’s largest production base, with an annual output of more than 300,000 electric cars. GRL provides fuses, fuse bases, and fuse switches for BYD’s Shenzhen production plant.

Customer Challenge

There are a large number of manipulators in the car production line, which costs are expensive. If the fuse cannot be quickly blown when it has an overload current encountered, it will damage a large number of manipulators and cause huge losses.

Solution

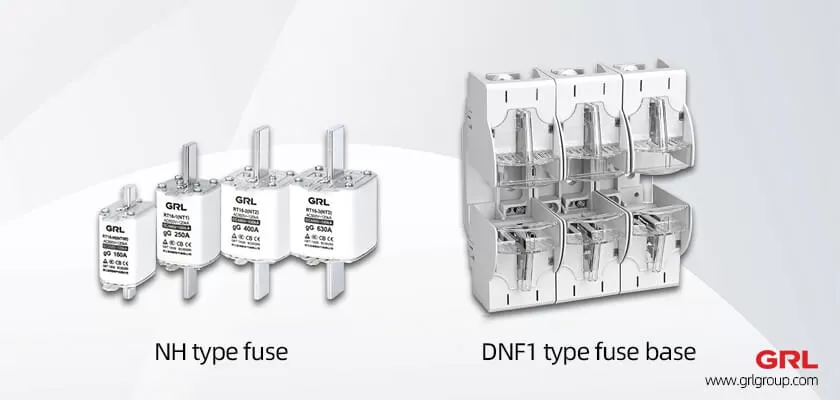

GRL Electric provides BYD with a type fuse, DNF1 type fuse base, and HH15 type fuse switch disconnector.

GRL develops low-power fuses for the BYD production plant. Even if the overload current is less than 10kA, it can be blown within 0.3 milliseconds to protect the end equipment.

At the same time, when the current is overloaded, the temperature rise of the fuse switch disconnector is less than 65K; the temperature rise of the fuse base is less than 50K.

GRL HH15 fuse-type isolating switch provides an operating mechanism outside the cabinet to meet the needs of the outside operation.

Application

GRL provides BYD with fuses, fuse switches, and fuse bases for over US$200,000 every year.

The equipment damage rate of BYD’s Shenzhen production line decreased by 5% due to the timely blowing of fuses.