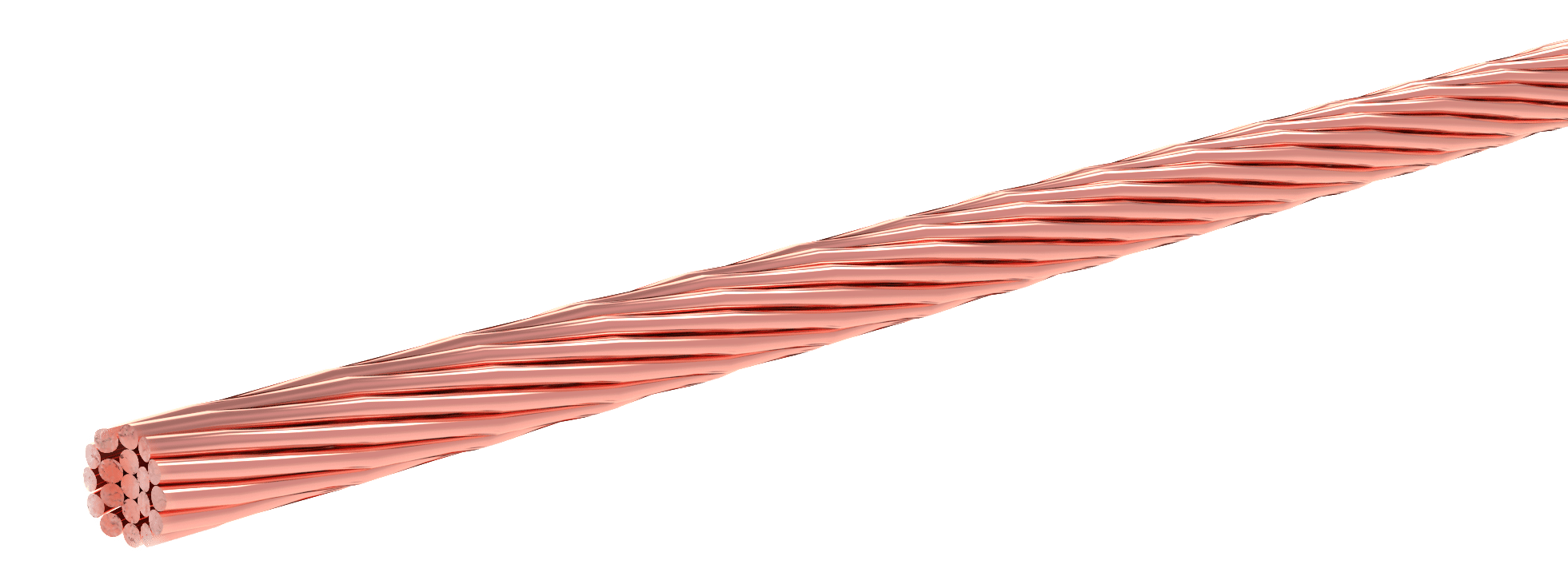

The DNJT(X) series Hard Drawn Copper Wire is a durable, high-strength conductor crafted from T2 copper with a purity exceeding 99.95%. It is specifically designed for applications requiring enhanced load-bearing capacity and robustness, making it ideal for industrial and high-demand electrical environments. This wire is produced by twisting larger-diameter copper strands, resulting in superior mechanical strength while maintaining excellent conductivity.

GRL DNJT(X) series adheres to the TB/T3111-2005 production standard and is available with bare copper or tin-plated finishes, customizable for various applications.

Material: T2 Copper, Copper Content > 99.95%

Single Wire Diameter: 1.70mm to 2.85mm

Cross-Sectional Area: 16mm² to 400mm²

Surface Treatment: Available in Bare Copper and Tin-Plated

Packaging: Packaged on sturdy wooden reels for convenient storage and transport

Production Standard: TB/T3111-2005

| Product Model | Nominal Cross-Sectional Area (mm²) | Calculated Cross-Sectional Area (mm²) | Wire Structure | Outer Diameter (mm²) | Weight (kg/km) |

| DNJT(X)-16 | 16 | 1.159 | 7/1.70 | 5.1 | 143 |

| DNJT(X)-25 | 25 | 0.735 | 7/2.14 | 6.42 | 226 |

| DNJT(X)-35 | 35 | 0.528 | 7/2.52 | 7.56 | 314 |

| DNJT(X)-50 | 50 | 0.371 | 7/3.00 | 9 | 445 |

| DNJT(X)-70 | 70 | 0.263 | 19/2.14 | 10.7 | 618 |

| DNJT(X)-95 | 95 | 0.197 | 19/2.52 | 12.6 | 852 |

| DNJT(X)-120 | 120 | 0.154 | 19/2.80 | 14 | 1057 |

| DNJT(X)-150 | 150 | 0.121 | 19/3.15 | 15.75 | 1339 |

| DNJT(X)-185 | 185 | 0.1 | 37/2.52 | 17.64 | 1660 |

| DNJT(X)-240 | 240 | 0.077 | 37/2.85 | 19.95 | 2123 |

| DNJT(X)-300 | 300 | 0.064 | 37/3.15 | 21.7 | 2594 |

| DNJT(X)-400 | 400 | 0.062 | 61/2.85 | 25.65 | 3502 |

Hard Drawn Copper Wire Features

1. High Strength

The hard-drawn structure with large-diameter strands provides high mechanical strength, allowing it to withstand greater physical stress compared to standard copper wires.

2. Enhanced Conductivity

The T2 copper material ensures excellent conductivity, enabling efficient power transmission even at high currents.

3. Durable Surface Treatment

Available in bare copper and tin-plated options, the tin-plated version offers additional corrosion resistance, extending the product’s lifespan in challenging environments.

4. Customizable Options

Various cross-sectional areas and structural configurations are available to meet specific project requirements, with customization options upon request.

5. Reliable Performance

Adhering to the TB/T3111-2005 standard, this wire guarantees consistent, high-quality performance in all applications, making it a trusted choice for demanding electrical installations.

Hard drawn copper Wire is widely used in heavy-duty electrical installations that demand high strength and durability. Its primary applications include power distribution in industrial facilities, power grids, and energy-intensive environments. The hard-drawn copper design is ideal for settings requiring stable, long-term electrical performance and resilience against mechanical stress.

It is commonly used in electrical panels, transformers, substations, and large-scale switchgear systems, where reliability and load-bearing capacity are critical.

The DNJT(X) series Hard Drawn Copper Wire combines durability, high conductivity, and robust design, making it ideal for a wide range of industrial power distribution needs. For more information or to discuss customization options, please contact our sales team.

What are tin-plated wire benefits?

Tin-plated copper wires combine the excellent conductivity of copper with the protective properties of tin, offering key benefits:

- Corrosion Resistance: Tin prevents oxidation, making wires durable in humid, marine, or chemical environments.

- Extended Lifespan: Reduces wear and degradation for longer-lasting performance.

- Improved Solderability: Tin’s low melting point ensures secure and efficient connections.

- Thermal and Chemical Resistance: Withstands high temperatures and exposure to chemicals.

- Low Maintenance: Requires less frequent replacement due to enhanced durability.

These features make tin-plated wires ideal for applications in marine, aerospace, electronics, and industrial systems.

Recommended Products

leave your question

![]()

GRL Electric Co., Ltd. is one of the leading companies in the Middle And High End market of low-voltage electric in China